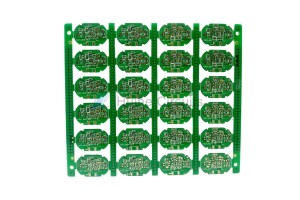

10 Ungqimba ENIG FR4 Via In Pad PCB

Nge-In Pad PCB

Ekwakhiweni kwe-PCB, imbobo edlulayo iyisikhala esinembobo encane ecwecwe ebhodini lesifunda eliphrintiwe ukuxhuma ojantshi bethusi kungqimba ngalunye lwebhodi.Kukhona uhlobo lwembobo ebizwa ngokuthi i-microhole, enembobo eyimpumputhe ebonakalayo endaweni eyodwa ye-ahigh-density multilayer PCBnoma imbobo engabonakali egqitshwe kunoma iyiphi indawo.Ukwethulwa kanye nokusetshenziswa okubanzi kwezingxenye zephinikhodi ezinomthamo omkhulu, kanye nesidingo se-PCBS yosayizi omncane, kulethe izinselele ezintsha.Ngakho-ke, ikhambi elingcono lale nselelo ukusebenzisa ubuchwepheshe bakamuva kodwa obudumile bokukhiqiza be-PCB obubizwa ngokuthi "Via in Pad".

Kumiklamo yamanje ye-PCB, ukusetshenziswa ngokushesha kwe- via in pad kuyadingeka ngenxa yokuncipha kwesikhala sezingxenye zezinyawo kanye nokuncishiswa okuncane kwama-coefficients omumo we-PCB.Okubaluleke nakakhulu, inika amandla umzila wesignali ezindaweni ezimbalwa zesakhiwo se-PCB ngangokunokwenzeka futhi, ezimweni eziningi, ikwazi nokugwema ukudlula umjikelezo ohlalwa idivayisi.

Amaphedi okudlula awusizo kakhulu kumiklamo yesivinini esikhulu njengoba ehlisa ubude bethrekhi futhi ngaleyo ndlela i-inductance.Kungcono uhlole ukuze ubone ukuthi umkhiqizi wakho we-PCB unemishini eyanele yokwenza ibhodi lakho, njengoba lokhu kungase kubize imali eyengeziwe.Kodwa-ke, uma ungeke ukwazi ukubeka nge-gasket, beka ngokuqondile futhi usebenzise okungaphezu kweyodwa ukunciphisa inductance.

Ngaphezu kwalokho, iphedi yokudlula ingasetshenziswa futhi esimweni lapho isikhala esinganele, njengakumklamo omncane we-BGA, ongakwazi ukusebenzisa indlela yendabuko yokukhipha abalandeli.Akungabazeki ukuthi ukukhubazeka kwe- through hole ku-welding disc kuncane, ngenxa yesicelo ku-welding disc, umthelela wezindleko mkhulu.Ubunkimbinkimbi benqubo yokukhiqiza kanye nentengo yezinto eziyisisekelo yizici ezimbili eziyinhloko ezithinta izindleko zokukhiqiza ze-conductive filler.Okokuqala, i-Via in Pad iyisinyathelo esengeziwe senqubo yokukhiqiza ye-PCB.Kodwa-ke, njengoba inani lezendlalelo lincipha, kanjalo nezindleko ezengeziwe ezihlobene nobuchwepheshe be-Via in Pad.

Izinzuzo Nge-Via In Pad PCB

Nge-pad PCBs anezinzuzo eziningi.Okokuqala, yenza kube lula ukuminyana, ukusetshenziswa kwamaphakheji okuhlukanisa kahle, kanye nokuncishiswa kwe-inductance.Ngaphezu kwalokho, ohlelweni lokusebenzisa i-pad, i-via ibekwa ngokuqondile ngaphansi kwamaphedi okuxhumana edivayisi, engafinyelela ukuminyana okukhulu kanye nomzila ongcono kakhulu.Ngakho-ke ingonga izikhala eziningi ze-PCB nge-pad yomklami we-PCB.

Uma kuqhathaniswa ne-vias eyimpumputhe kanye ne-vias engcwatshwe, nge-pad inezinzuzo ezilandelayo:

Ifanele imininingwane yebanga BGA;

Thuthukisa ukuminyana kwe-PCB, gcina isikhala;

Ukwandisa ukuchithwa kokushisa;

Ifulethi ne-coplanar enezesekeli zengxenye inikezwa;

Ngenxa yokuthi awukho umkhondo we-dog bone pad, i-inductance iphansi;

Khulisa amandla kagesi wembobo yesiteshi;

Nge-In Pad Isicelo Se-SMD

1. Faka imbobo nge-resin bese uyinamathisela ngethusi

Ihambisana ne-BGA VIA encane e-Pad;Okokuqala, inqubo ihilela ukugcwalisa izimbobo nge-conductive noma non-conductive material, bese ufaka izimbobo phezulu ukuze unikeze indawo ebushelelezi yendawo eshiselayo.

Imbobo yokudlula isetshenziswa ekwakhiweni kwephedi ukukhweza izingxenye embotsheni yokudlula noma ukwelula amalunga e-solder ekuxhumekeni kwembobo yokudlula.

2. Ama-microholes kanye nezimbobo zibekwe phezu kwephedi

Ama-Microholes ayizimbobo ezisekelwe ku-IPC ezinobubanzi obungaphansi kuka-0.15mm.Kungaba imbobo edlulayo (ehlobene ne-aspect ratio), noma kunjalo, ngokuvamile i-microhole iphathwa njengembobo eyimpumputhe phakathi kwezingqimba ezimbili;Ama-microholes amaningi abhobozwa ngama-lasers, kodwa abanye abakhiqizi be-PCB nabo babhoboza ngezingcezu zemishini, ezihamba kancane kodwa ezisikwa kahle futhi ezihlanzekile;Inqubo ye-Microvia Cooper Fill iyinqubo yokubeka i-electrochemical yezinqubo zokukhiqiza i-PCB ye-multilayer, eyaziwa nangokuthi i-Capped VIas;Nakuba le nqubo iyinkimbinkimbi, ingenziwa ibe yi-HDI PCBS lapho iningi labakhiqizi be-PCB lizogcwaliswa ngethusi elincane.

3. Vimba imbobo nge-welding resistance layer

Imahhala futhi iyahambisana ne-solder SMD pads enkulu;Inqubo yokushisela yokumelana ne-LPI ejwayelekile ayikwazi ukwenza ukugcwaliswa ngembobo ngaphandle kwengozi yethusi elingenalutho emgqonyeni womgodi.Ngokuvamile, ingasetshenziswa ngemva kokuphrinta kwesikrini sesibili ngokufaka i-UV noma i-epoxy solder ukumelana nokushisa emigodini ukuze uyixhume;Kubizwa ngokuvinjwa.Ukuxhuma ngembobo ukuvinjwa kwezimbobo ngokusetshenziswa kokumelana nokuvimbela ukuvuza komoya lapho kuhlolwa ipuleti, noma ukuvimbela amasekhethi amafushane ezinto eduze kwendawo yepuleti.

-300x225.png)